Thompson Investment Casting Process

Step 1

Tool Design and Manufacture

A wax injection mold is designed and built to produce castings per customer specifications.

Step 2

Wax Production

A wax pattern of recyclable material is produced from the wax injection mold.

Step 3

High Volume Production

Multi-cavity tools are used to expedite the volume of wax production.

Step 4

Pattern Assembly

Thompson Investment Casting’s unique method of gating and treeing systems assures sound castings at a minimum cost.

Step 5

Shell Molding

The pattern assembly is systematically dipped into a ceramic slurry, coated with a refractory material and dried. The process is repeated until the desired thickness and strength is achieved.

Step 6

Ceramic Shell Drying

Between coatings, the ceramic shells are dried in an atmospherically-controlled environment.

Step 7

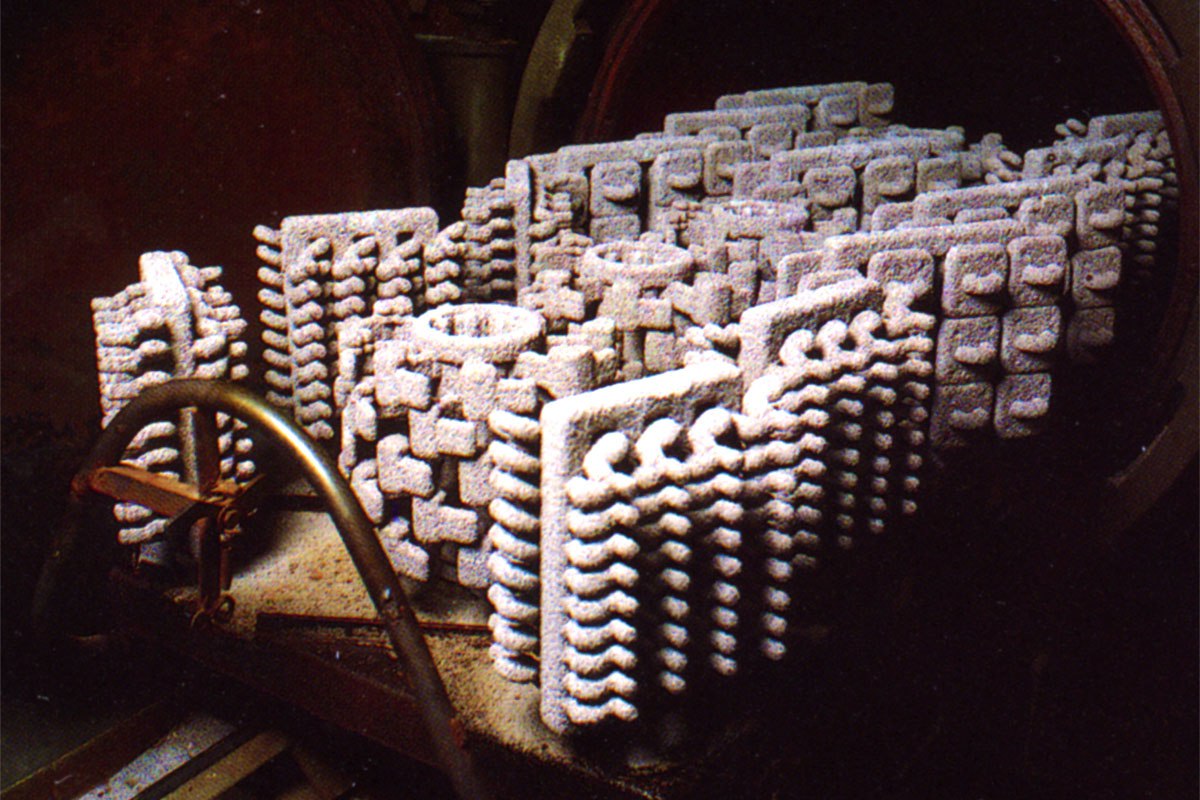

Autoclave

Using regulated steam pressure, an autoclave melts and reclaims the wax from the ceramic shells.

Step 8

Shell Curing

High temperature ovens cure and preheat the ceramic shells prior to pouring the molten metal.

Step 9

Casting

Pre-heated molds are poured utilizing a unique process which facilitates the production of thin walls and intricate detail while enhancing the surface.

Step 10

Knock Out & Cut Off

The ceramic shell is removed, the cluster is cleaned, & the castings are cut free from the gating system.

Step 11

Machining & Finishing

After cut off and gate removal, all secondary finishing operations are performed.

Step 12

Inspection & Testing

Castings are inspected & precisely tested according to customer specifications and requirements.